Motor Analysis

Improve Motor Performance and Extended Motor Life

At Enerdoor, we specialize in providing comprehensive motor analysis services to enhance the efficiency and reliability of your automation and industrial systems. Our seasoned professionals leverage advanced techniques and state-of-the-art equipment to deliver precise and reliable data on your motor performance.

With our motor analysis services, you can proactively identify potential issues before they result in costly downtime or equipment failure. We adopt a collaborative approach, working closely with you to craft customized solutions that align with your specific needs, whether it's predictive maintenance, performance optimization, or troubleshooting support.

Our overarching goal is to ensure that your automation and industrial systems consistently operate at peak performance, maximizing efficiency, and minimizing downtime.

Key Highlights of Our Motor Analysis Services:

Specialized Analysis: Our motor analysis services are designed for motors up to 690 Vac, focusing on waveform, voltage, current form, and shaft voltage directly on the motor. This in-depth analysis helps us pinpoint the root causes of premature motor failure, offering cost-effective and prompt solutions to maintain optimal motor performance and prevent production downtime.

Energy Insight: Did you know that electric motors consume 19% of the total energy produced in the United States? Moreover, over 70% of electrical energy in manufacturing, and 90% in the processing industry, is consumed by motor systems. Motors controlled by variable frequency drives (VFDs) offer energy savings but can pose challenges like overvoltage spikes, heat, and power loss.

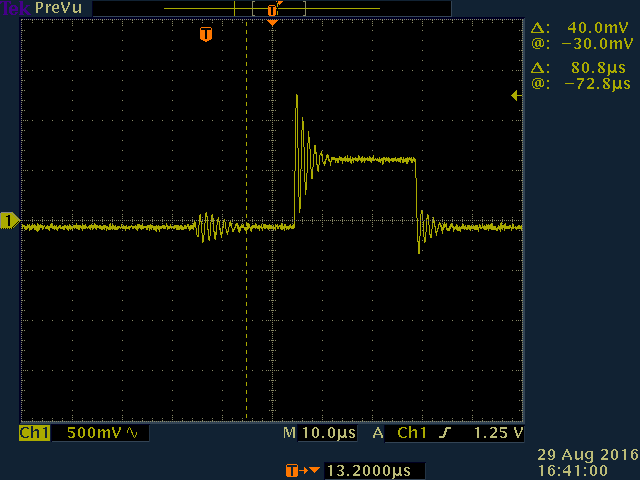

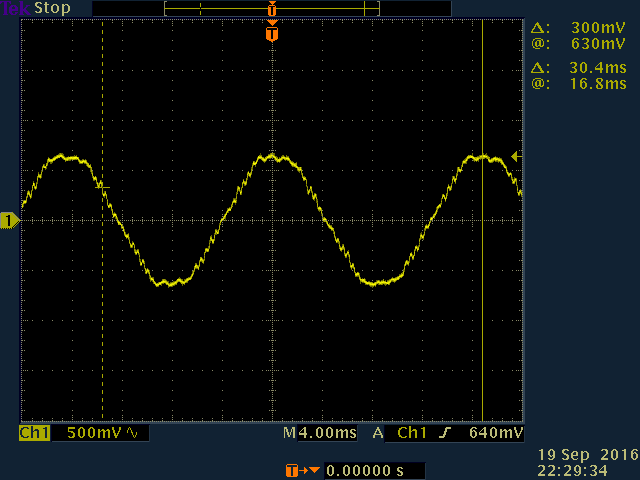

Overcoming Challenges: We address challenges associated with VFD-controlled motors, such as square wave and overvoltage spikes (dV/dt), which contribute to heat stress, winding, insulation, and bearing damage. By eliminating these spikes using our innovative technology, the sine wave filter, we reduce heat stress, enhance motor performance, and extend motor life.

RF Noise Elimination: Enerdoor introduces a groundbreaking solution for eliminating RF noise with the sine wave filter. Unlike traditional shielded cables that contain noise, our technology eradicates RF noise, offering superior performance. The Enerdoor sine wave series covers a range from 0 to 880A, with high-frequency solutions available.

| Standard waveform measured when the motor is controlled by a VFD | Standard waveform measured when the motor is controlled by a VFD, with an Enerdoor sine wave filter installed |

|

|

Ready to Elevate Your Motor Performance?

Enerdoor's unique position as both an EMC filter manufacturer and a field testing veteran establishes us as an industry leader in motor analysis. Our expertise extends to protecting motors from overvoltage transients and spikes.

Contact Enerdoor today to learn more about our motor analysis services, request a free quote, or discuss your specific requirements. Experience the difference with our innovative solutions and industry-leading expertise.

A selection of standard applications and recommended Enerdoor solutions:

|

Example of Applications |

Product Description |

Enerdoor Solution |

|

Cable < 100 feet |

Chokes |

|

|

Cable > 100 feet |

Sine wave filter |

|

|

Large motor > 100HP |

Snubber |

|

|

Frequency output > 75Hz cable < 100 ft |

High frequency inductance |

|

|

Frequency output > 75Hz cable > 100 feet |

High frequency sine wave filter |

|

|

Servo drive with closed loop control |

Chokes |